|

|

|

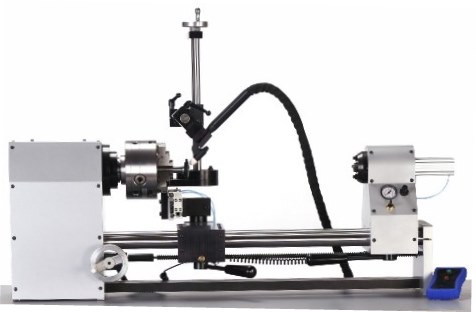

Precision Welding Lathes

|

| For highly repeatable weld results with extremely consistent welding speed and minimal run out Improve Weld Quality · Increase Weld Output · Lower Labor Costs |

The Pro-Fusion Precision Welding Lathe is designed to allow unskilled personnel to consistently produce high quality welds on a wide range of circumferential parts. With over 20 years of welding experience, Pro-Fusion can assist in weld schedule development and tooling in order to provide a complete, turn-key automatic welding system.

|

|

Pro-Fusion Lathes As Part of Complete Automated Welding Systems

A complete Pro-Fusion welding system offers computer control of critical welding parameters including programmable peak and background welding current, arc pulsation, upslope, downslope, pre and post purge gas control. Pro-Fusion TIG/Micro-TIG and Plasma/Micro-Plasma welding power sources are available as a completely integrated package with a Pro-Fusion lathe. An optional touch-retract system allows for precise tungsten to work gap settings for additional torch positioning.

|

| Click for larger image |

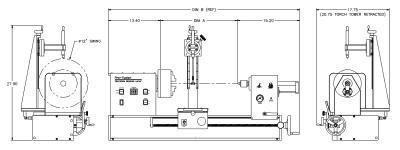

Pro-Fusion Precision Welding Lathe

Specifications

- RPM 0.5 - 25 Standard

- Max Diameter Part: 12�

- 3-Jaw Tru-Set Chuck Standard

- 5C Chucks, pneumatic or manual on request

- Distance Between Centers: 16�

- Custom Lengths Readily Available

- Tailstock: Air actuated, 3� travel, pressure & speed controls

- Torch Tower: Pneumatic advance and retract with speed controls, X, W, Z axis w / fine adjustments

- Torch Mounting Block: 360� rotation & right or left hand set up

- Overall Length: 45�

- Height of Headstock: 16 5/8�

- Overall depth: 26�

- Weight: 230 lbs

- Input Voltage: 115 VAC

- Controls: Forward, Reverse, Jog, Local and Remote

- Custom Configurations on Demand

About Pro-Fusion

Copyright © 1999-2019 Pro-Fusion by Elderfield & Hall.

10901 McBride Lane

Knoxville TN 37932

Tel: 865.671.7682

email: sales@pro-fusiononline.com

Privacy Policy, Shipping, Terms & Conditions